What Are the Benefits of Tier 4 Final Technology?

technology

Introduction

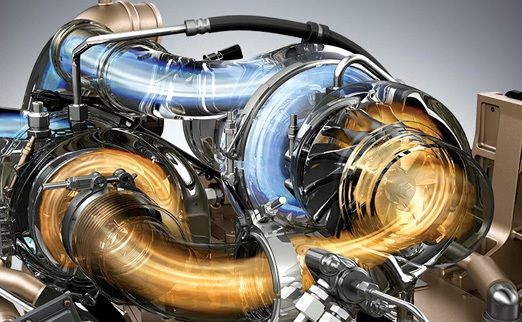

An engine or motor is the heart of any machine because it helps in the conversion of one form of energy into another. For example, electric motors convert electrical energy into mechanical energy. Designing an engine involves using complex thoughts and turning them into a product.

Volvo construction equipment has been one of the best manufacturing companies for many years and holds expertise in designing machines as well as engines.

Volvo continues to upgrade its industrial products and design better than before, a feat that must be appreciated. Their engines meet all the demands covered in the latest premium Stage IV/EPA Tier 4 Final technology.

The customers are also provided with solutions that offer better knowledge, less maintenance, upgraded solutions, more productivity, and reduction of the maintenance cost.

Selective Catalytic Reduction

Selective catalytic reduction involves injecting a solution known as DEF (Diesel Exhaust Fuel) into the exhaust where it’s heated after which ammonia is produced. It causes a chemical reaction that converts NO to nitrogen and carbon dioxide. Since these gases exist in the environment naturally, they don’t count as harmful emissions.

Engine Management System (EMS)

This management system helps in managing the engine performance for any new operating system. The latest upgraded EMS helps a powerful processor withstand any condition, all the while supporting the in-built specifications to be more accurate.

Producing High Torque at Low Rpm

Volvo engines always have a longer life because they manufacture engines that do not need to work much or require much maintenance. They always try to generate higher performance at low engine speeds, and the latest premium Volvo’s Stage IV/Tier 4 final engines are known for their ability to produce higher torque at a lower rpm.

Easier Installation and More Reliable

SCR technology is a beneficial process in the reduction of emissions. There are various ways involved in the designing and installation of SCR, but the technique used by Volvo Penta is the most reliable one. While others make the installation complex by using the C-EGR system, Volvo uses only two elements – SCR and light EGR because using more parts for installation increases the risk of system malfunction.

Benefits of Using Volvo Penta Solution

-

Maximized Power Output: As per the Tier 3 regulation, Volvo has introduced advanced combustion technology (V-ACT) which, when combined with the SCR technology, helps in the conversion of more fuel into mechanical power but it does not help in reducing the heat generated during this conversion. This proves that the power output maximizes with the use of any other engine. Using small-sized engines can be the solution as they facilitate easy and simplified installations and cost less. With the use of Volvo Penta engines, the power output can be largely minimized.

-

Price reduction: With the use of engines built with the SCR technology, there is a reduction in the maintenance cost, thereby providing a larger life engine with higher efficiency.

Conclusion

This latest premium Stage IV/Tier 4 final technology is the most reliable and meets most of the customer requirements by giving them a highly efficient engine with low maintenance cost and optimized design.

You must be logged in to comment

Login now